Stamping

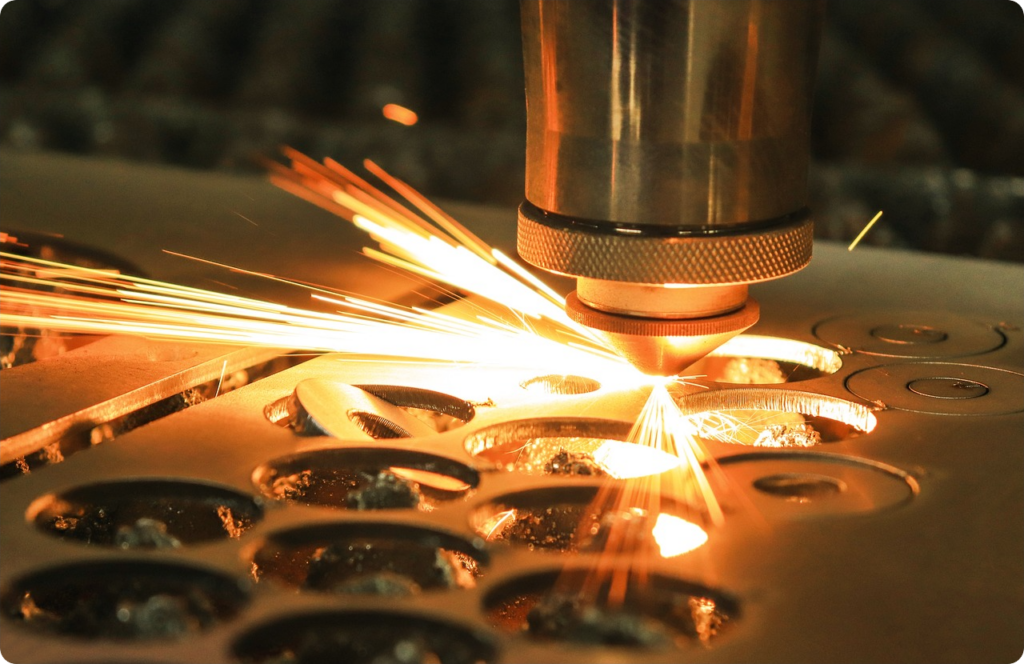

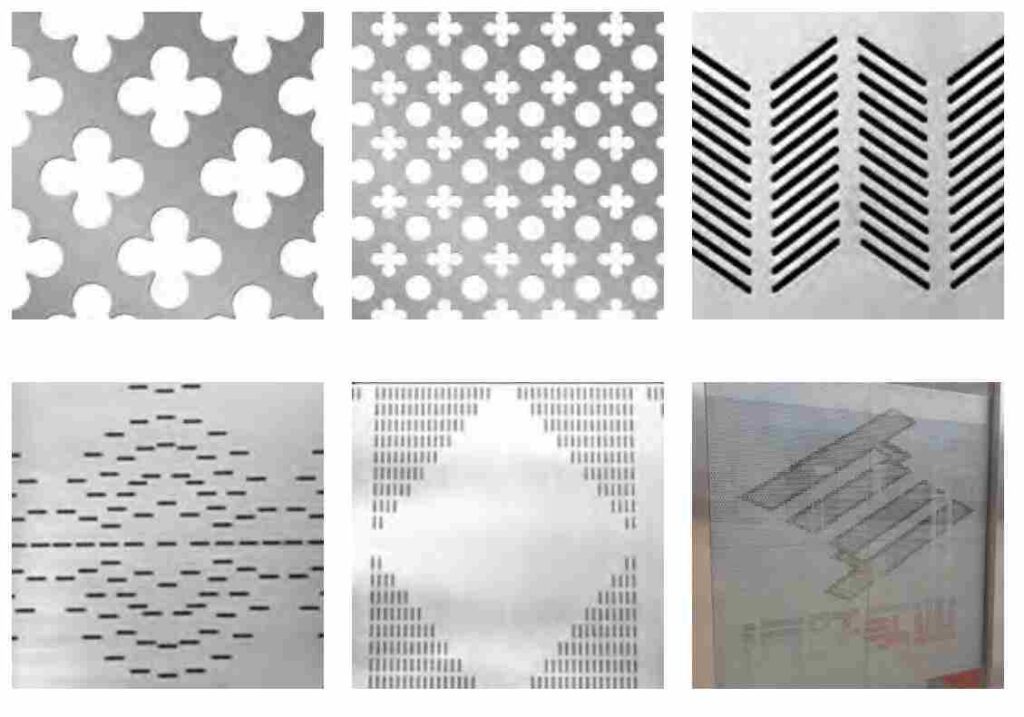

Stamping processing technology is a precision forming process implemented on metal sheets, which applies pressure to cause plastic deformation of the metal, thereby forming the desired shape of the workpiece. This technology is efficient, labor-saving, cost-effective, and capable of producing high-precision and stable quality parts in large quantities, making it widely used in the industrial field. For the cutting and forming of special materials, stamping technology also demonstrates excellent processing efficiency and quality.